Success Syndrome teaches us -‘How NOT to Design’

“… (The design mistake) It was repeated 3000 years ago, 300 years ago, just 30 years ago and will likely to be repeated even today.”

“…Possibly the greatest tragedy underlying design errors & the resultant failures is that many of them do indeed seem to be avoidable, yet one of the potentially most effective means of improving reliability in engineering appears to be the most neglected.”

-Henry Petroski in his book, “Design Paradigms Case Histories of Errors and Judgements in Engineering”.

Catastrophes affect many lives and bring in direct or hidden detrimental impacts on economies. If it is caused accidentally by human acts, then it is the responsibilities of an individual or an institute or a corporate to flag the cause of such disasters or catastrophes to the world.

Let us focus on product design disasters. There are two kinds of disasters; one is due to poor quality of materials or workmanship, and the second one is due to design faults. A successful engineering is all about not just understanding how things break or fail; but at what cost, matters a lot. There are textbook examples on these two types failures. The ship that broke into two pieces in the middle of the ocean and the house that caught fire due to the gas leakage in the PE pipe are the standing examples for a comparison (read here for more details).

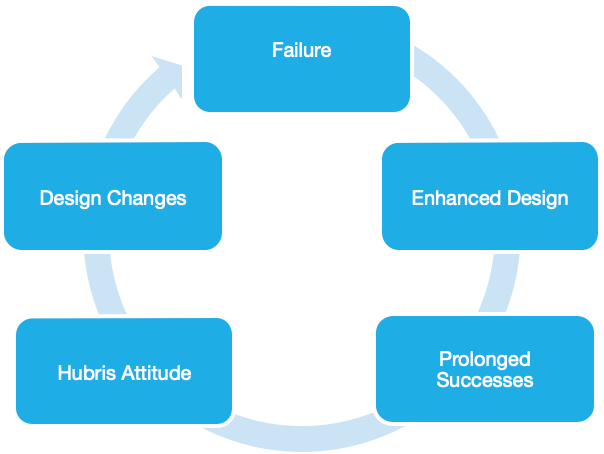

Browsing the history of design failures, it all starts with the careful design modifications and successful implementations. After a prolonged success of the product, the designers develop a hubris attitude that leads to faulty-designs lurking in the darkness for a right moment. Then comes a catastrophe that exposes the design. The design team now gets back to the drawing board for careful modifications. This cycle goes on endlessly for 3000 years and even today.

Conceptual Stage

Errors can sneak in at any stage of the evolution of a design. The most of the elusive flaws usually happens at the conceptual stage.

Paconius, in the 1st century BC, won a contract to move a large massive pedestal stone from its quarry in Greece. In order to save costs, he redesigned the process of transportation and made a few changes accordingly. Unlike his contemporaries who hauled them through the axles, he wound the ropes around the pedestal to roll down the streets of Selinous to the temple of Apollo. The book “The Ten books of Architecture” by Roman Vitruvius elaborates his unsuccessful plan which ended him up insolvent. (read here for more details)

Such stories did not stop even in the era of computer. On the 10th of June 2000, a grand ceremony was held either side of the river Thames, London to inaugurate the Millennium Bridge. The architects of the bridge claimed it to be an innovative blade of light structure. However, the show ended up differently. No sooner did the passers-by cross the bridge, than it started swaying heavily due to the effect of the synchronous lateral excitation which its engineers failed to consider.

Hence, it is important to articulate the design right at the conceptual stage. No prototypes are usually made for big structures such as bridges, spacecrafts to pinpoint conceptual mistakes out. Even if they do, dimensional effect hinder the real functionality.

Design Changes

Even though elusive flaws in designs catch our eyes and get rectified at the early stages, the products may still fail when the design changes are not meticulously carried out. In fact such design errors can fill the pages of several thick books.

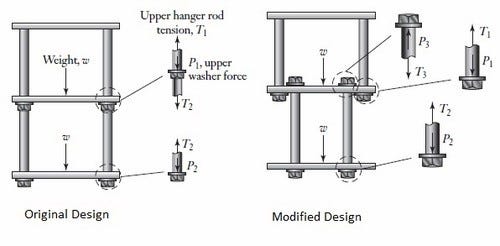

An infamous incidence at Hyatt Regency, Kansas in July 17th, 1981 is often cited as an example of design changes. The conceptually strong design of the two floor walkway of the hotel collapsed merely a few months after its construction (read here for more details). During the design change, the long connecting rods were made into two pieces and connected with the middle floor directly. Unfortunately, the stress concentrations in the nuts connecting the floors were not taken into consideration in the new design. Finally the stress in the nuts exceeded the limit and the floor collapsed killing 114 people.

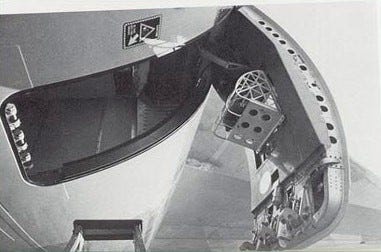

Another famous story of “door opening system” goes this way. There was a confusion among NASA engineers while designing the door that was supposed to open outward for Apollo 1 module. Following an accident of a different space module in which outward opening door caused the gushing of water inside, after its splashdown, NASA engineers decided to redesign the door of Apollo1 so that it opened inward with the slightly increased pressure inside the module.

Unfortunately during one of the rehearsals, a spark inside the module, ignited a deadly fire accident killing all its crew members. The astronauts could not open the door inward owing to the high pressure caused by the temperature.

Similar design mistake was done in DC 10. Its bottom door was designed to open outward in order to save some cargo space. Unfortunately, the cabin pressure pushed the door open in mid-air killing all its passengers. A detailed read is available in this link. (The following image was taken from the same.)

The effect of design changes can show up at any stage and the new lessons are learnt every time out of it. The “Bent” Pyramid which was constructed 5000 years ago, got its name due to its strange structure. It was initially built out to be inclined at 54 degree but changed to 43 degree halfway in order to prevent its collapse.

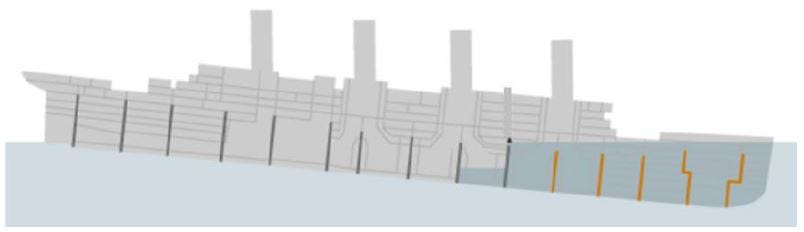

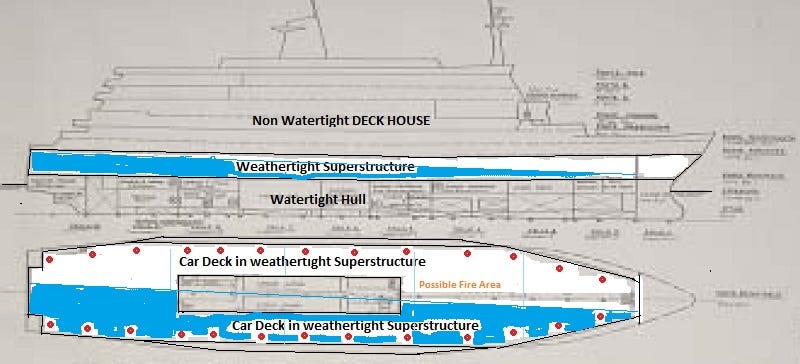

Hence the judgement, which plays a crucial role, is very important at every stage of the design. Else catastrophes like of HS Titanic in 1911 or MS al Salam in 2009 may happen (read here for more details).

The judgement during the design-change leads into two new paths namely ‘dimensional effect’ and ‘redundancy’.

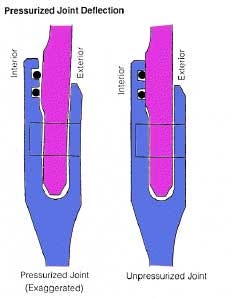

One of the natural tendencies of any designer is to provide redundancy for safety, only to become detrimental in the end. The space shuttle Challenger would have not probably burst in the midair if the additional O ring was not incorporated unnecessarily, in the previously “proven” launcher design.

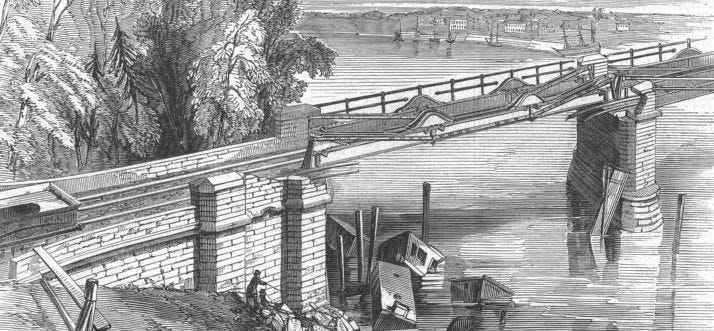

The dimensional effect is also very important factor in which undesirable new effects would pop up with no warnings. The Dee Bridge is one of the classic examples of the dimensional effect. In this case, the span length was slightly increased from the “successfully proven” earlier bridge designs. The bridge collapsed a few days after the construction, when a passenger train was about to complete its ride, in 1847.

Success Syndrome

All of the above occurrences can be attributed to the effect called “Success Syndrome”, which leads to a hubris attitude among designers. Technically known as Normalisation of Deviance, it results from their overconfidence or wrong judgements as a results of pro-longed success.

When they make design changes with this attitude, they mostly tend to miss vital considerations in designs. After the worst happened, they all sit down with fresh attentive minds for enhancements. Thus the product designs get stabilized till the designers develop hubris attitudes. It has been repeated in a cycle from the days of Greeks to the age of computer.

Prevention?

As I mentioned earlier, it is the responsibility of everyone of us as an individual or a corporate or an institute to share at least the crux of the design failures without revealing much details (if backfires).

In other words, we need a universal database of all design related disasters. Of late 1990s, the expert system was introduced to help designers but in vein. It could not achieve the very purpose of the mission. However, it still helps the designers meet the regulations and other safety aspects. The computational complexities has been the major tumbling block to predict such failures numerically or analytically.

Now in the era of machine learning, advanced computation techniques, IoT technologies and the “promising” quantum computing, it is very much possible to flag the potential disasters right at the design stage as well as much ahead of the occurrence.

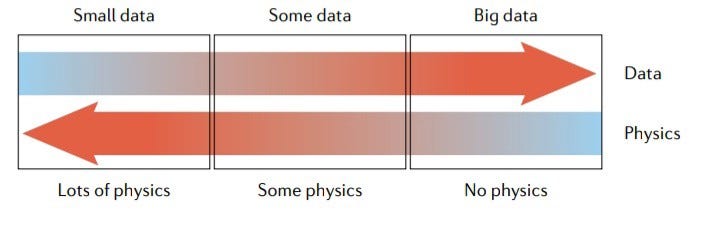

The Physics Based Neural Network (/ Deep Learning) is one of the emerging powerful tools to analyse various geometries of the design faster than the numerical methods. However, the major limitation with PBDL is, the boundary & the initial conditions are fixed.

In fact, the prediction of failures exactly needs the varying boundary & initial conditions with the fixed geometrical models. In case of the Millennium Bridge, the engineers must have surely carried out the numerical analysis, but probably with the (assumed) fixed boundary & initial conditions. In my guess, the experienced architects would have focused only at the tensile and the bending analyses, without paying attention to the effect of the lateral excitation.

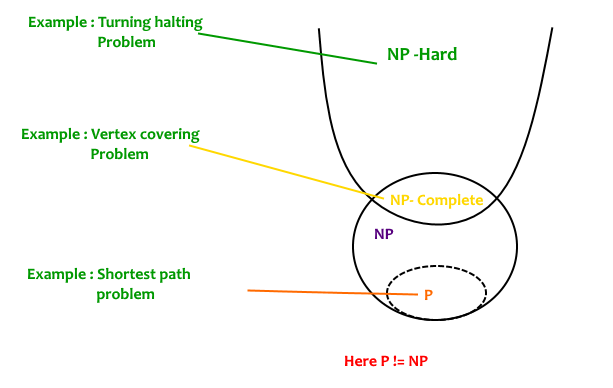

The analysis of the design for various boundary & initial conditions fall into the category of the high computational complexities, aka NP problems. Solving a linear equation for a large dimensional matrix is hard. Also failure predictions with the Fault Tree Analysis needs the solver of complex combinatorics problems.

Most of the NP and NP Complete problems are supposedly solved “only” by the quantum computers or other nondeterministic computing processes. Once the universal quantum computers are realised, the quantum numerical methods may be made possible to predict such failures.

In the meantime, Fujitsu’s Digital Annealer offers a platform to solve optimisation problems which can be used in design analysis to some extent. I will post more on it after running some of our design related solvers on the annealer.

Hey wait! Why don’t we imbibe the bio-mimicry approaches in our designs? Of course the analysis are very cumbersome. I will write more biomimicry as well.

Comments

Post a Comment